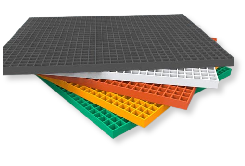

GFRP Moulded Gratings

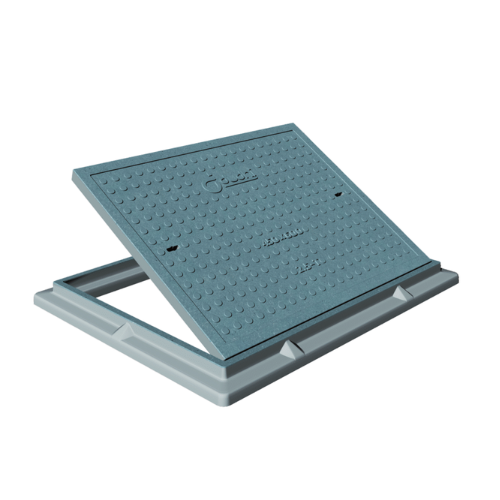

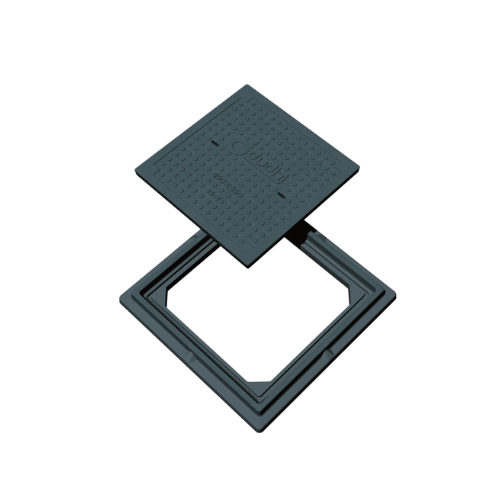

Dudhi Dyna Guard STA: GFRP Moulded Gratings

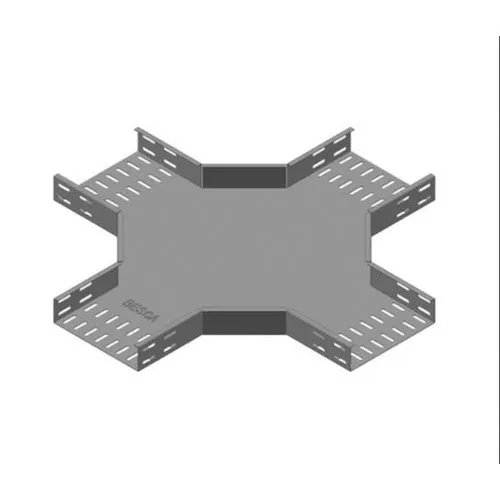

DynaGrate STA: Moulded gratings are widely used in various applications due to their lightweight, corrosion-resistant, and durable properties. These gratings are manufactured by combining resin with fiberglass reinforcement through a molding process, resulting in a strong and versatile material.

- Industrial Platforms and Walkways

- Marine and Waterfront Structures

- Commercial and Recreational Facilities

- Water and Wastewater Treatment

- Power Generation Plants

- Mining and Mineral Processing

- Transportation Infrastructure

- Chemical Processing Plants

- Food and Beverage Industry

- Oil and Gas Industry

- Safety and Access Applications

DynaGuard STA : GFRP Moduled Gratings

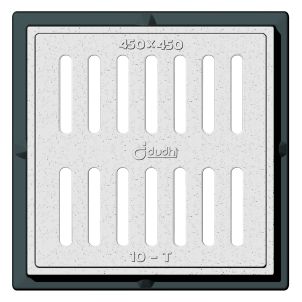

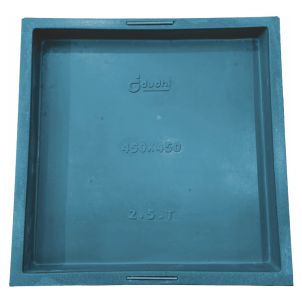

| Grating Thickness | Mesh/Rib Description | Panel Sizes Available (MM) | Weight (kg/m2) | % Open Area | Loading Capacity (UDL) (kg/SQM) |

|---|---|---|---|---|---|

| 1”(25 mm) | Square Mesh(38 x 38 mm ) RibThickness-(5-7 MM) | 1220X3660 | 12.2 | 68% | 450 |

| 1-1/4”(30 mm) | Square Mesh(38 x 38 mm ) RibThickness-(5-7 MM) | 1220X3660 | 15.62 | 68% | 500 |

| 1-1/2” 40 mm) | Square Mesh(38 x 38 mm ) RibThickness-(5-7 MM) | 1220X3660 | 18.55 | 68% | 750 |

Application Area

Dudhi DynaGrate STA Fiber Reinforced Polymer (FRP) Moulded gratings are widely used in various applications due to their lightweight, corrosion-resistant, and durable properties. These gratings are manufactured by combining resin with fiberglass reinforcement through a moulding process, resulting in a strong and versatile material. Here are some common applications for FRP Moulded gratings:

Industrial

Floor Gratings

Walkway Grating

Marine & Coastal Environments

Deck Grating

DynaGuard STA : GFRP Moduled Gratings

| Blocks | Blocks | Blocks | Blocks | Blocks | Blocks | Blocks | Blocks |

|---|---|---|---|---|---|---|---|

| 43 | 195 | 347 | 499 | 651 | 803 | 955 | 1107 |

| 81 | 233 | 385 | 537 | 689 | 841 | 993 | 1145 |

| 119 | 271 | 423 | 575 | 727 | 879 | 1031 | 1183 |

| 157 | 309 | 461 | 613 | 765 | 917 | 1069 | 1222 |

| 45 | 501 | 957 | 1413 | 1869 | 2325 | 2781 | 3237 |

| 83 | 539 | 995 | 1451 | 1907 | 2363 | 2819 | 3275 |

| 121 | 577 | 1033 | 1489 | 1945 | 2401 | 2857 | 3313 |

| 159 | 615 | 1071 | 1527 | 1983 | 2439 | 2895 | 3351 |

| 197 | 653 | 1109 | 1565 | 2021 | 2477 | 2933 | 3389 |

| Blocks | Blocks | Blocks | Blocks | Blocks | Blocks | Blocks | Blocks |

|---|---|---|---|---|---|---|---|

| 235 | 691 | 1147 | 1603 | 2059 | 2515 | 2971 | 3427 |

| 273 | 729 | 1185 | 1641 | 2097 | 2553 | 3009 | 3465 |

| 311 | 767 | 1223 | 1679 | 2135 | 2591 | 3047 | 3503 |

| 349 | 805 | 1261 | 1717 | 2173 | 2629 | 3085 | 3541 |

| 387 | 843 | 1299 | 1755 | 2211 | 2667 | 3123 | 3579 |

| 425 | 881 | 1337 | 1793 | 2249 | 2705 | 3161 | 3617 |

| 463 | 919 | 1375 | 1831 | 2287 | 2743 | 3199 | 3655 |

DynaGuard STA : GFRP Moduled Gratings

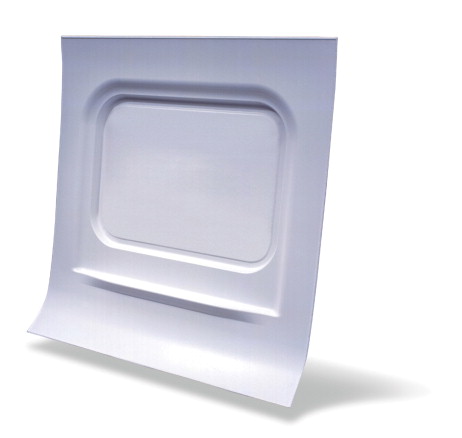

Physical Properties:

Density: Varies depending on the resin matrix and reinforcement, typically around 1.6 – 2.0 g/cm³.

Thermal Conductivity: Low thermal conductivity compared to metals.

Expansion Coefficient: Minimal expansion and contraction with temperature changes.

Electrical Properties:

Non-Conductive: FRP gratings are non-conductive and offer excellent electrical insulation properties.

TECHNICAL & PHYSICAL PARAMETERS

Mechanical Properties:

Tensile Strength: Typically in the range of 20,000

- 30,000 psi (138 – 207 MPa).

Flexural Strength: Around 25,000 – 40,000 psi (172

- 276 MPa).

Compressive Strength: Approximately 20,000 – 30,000 psi (138 – 207 MPa).

Impact Strength: High impact resistance due to the composite nature of the material.

Load-bearing capacity:

Load Ratings: Load-bearing capacities vary based on the mesh size, panel thickness, and design specifications. Often specified as uniform and concentrated load limits.

Panel Sizes and Mesh Configurations: Available in various panel sizes, mesh configurations, and thicknesses. Customizable to suit specific project requirements.

Mild Steel Grating

Material Composition: Made of steel, which can corrode and rust over time, especially in corrosive environments.

Corrosion Resistance: Susceptible to corrosion and rust, especially in environments with moisture or exposure to

chemicals.

Weight: Heavier than DUDHI DYNAGRATE STA FRP, requiring more effort and equipment for handling and installation.

Strength-to-Weight Ratio: Strong, but its weight can limit its practical load-bearing capacity compared to DUDHI DYNAGRATE STA FRP.

Electrical Conductivity: Conductive, posing a risk in electrical and electronic environments.

Maintenance: Needs regular maintenance to prevent rust and corrosion, involving painting, coatings, and potential replacements

Fire Resistance: Vulnerable to fire and may require additional fireproofing measures.

Installation: Heavier and requires more labour and equipment for

installation.

Aesthetic Options: Generally lacks aesthetic customization options.

Cost: Lower initial cost but higher maintenance and replacement costs due to corrosion and rust.

Environmental Impact: Resource-intensive to produce and can contribute to environmental degradation if not properly maintained.

DynaGrate STA

Material Composition: Manufactured with Special Grade of fiberglass reinforced with plastic resin. Offers excellent corrosion resistance, high strength-to-weight ratio, and

Non-conductivity.

Corrosion Resistance: Highly resistant to corrosion from chemicals, moisture, and environmental elements. Suitable for harsh and corrosive environments.

Weight: Lightweight, making transportation, handling, and installation easier. Reduces the need for heavy equipment during installation.

Strength-to-Weight Ratio: Offers a high strength-to-weight ratio, allowing it to handle heavy loads while remaining lightweight.

Electrical Conductivity: Non-conductive and offers excellent electrical insulation properties, making it safe for use in electrical environments.

Maintenance: Requires minimal maintenance due to its resistance to corrosion and chemicals.

Fire Resistance: Dudhi DynaGrate STA FRP gratings are manufactured with fire-retardant additives, enhancing its fire resistance.

Installation: Lightweight and can be easily cut and installed with basic tools. Suitable for areas where heavy equipment is impractical.

Aesthetic Options: Available in various colors and surface patterns for aesthetic

integration.

Cost: Initial cost might be higher, but lower maintenance and longer lifespan can make it cost-effective over time.

Environmental Impact: More environmentally friendly due to recyclability and lower resource consumption during production.

Know more about us and our range of products, you can log on to our website www.dudhi.in or simply write us on info@dudhi.in