Overview

The advantages of choosing a good manufacturer’s Glass Fiber Reinforced Polymer (GFRP) drainage channel

Choosing a good Glass Fiber Reinforced Polymer (GFRP) drainage channel manufacturer like Dudhi Industries Pvt. Ltd. can bring significant benefits, including long lifespan, easy maintenance, environmental friendliness, stable quality, and professional after-sales service. So, it’s always better to do proper research before buying any drain for your construction project, to ensure effectiveness and durability in the long run.

Dudhi GFRP (Glass Fiber Reinforced Polymer) Drain Channel

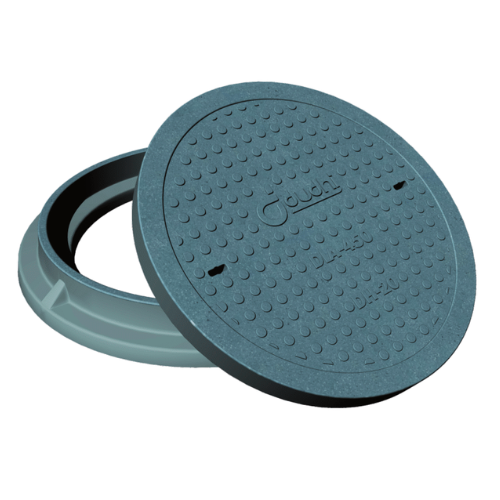

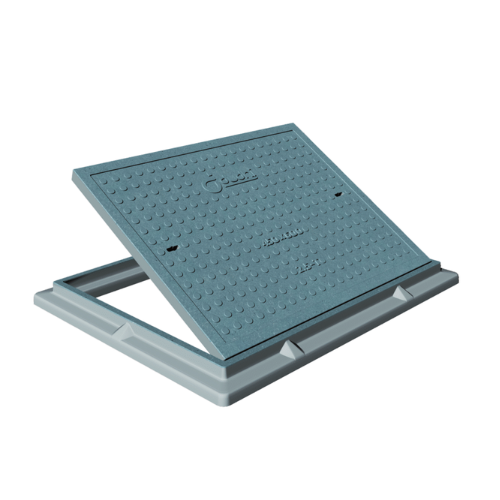

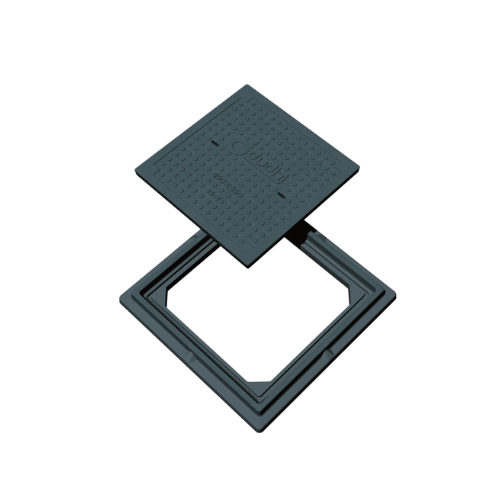

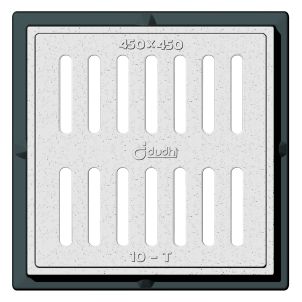

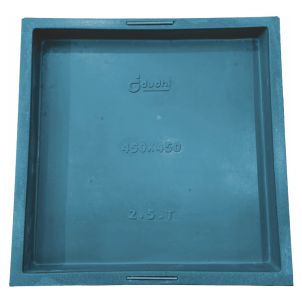

- FRP/GRP/Composite manhole covers are tested for load bearing and permanent seta as per BS EN 124:1991 and IS 1726. BS EN 26 is testing code worldwide for Manhole covers in Cat iron, Ductile iron and other materials also. Permanent deformation in cover after multiple loading within a short time as specified in the code.

- HSN Code : 392690

- GST : 18%

Shock Proof

Zero Maintenance

High-Load Capacity

Leak Proof

No Color Fading

| Technical & Physical Parameters | |

|---|---|

| Longitudinal Strength | 250-600 Mpa |

| Compressive Strength | 300-600 Mpa |

| Stretch Modulus | 25-35 Gpa |

| Break Elongation Ratio | 1.3-10.0% |

| Bending Strength | 700-1400 Mpa |

| Poission–Ratio | 0.35 |

| Relative Density | 1.11-1.15 |

| Water-Absorptive (24h) | 10-30 mg |

| General Application Temperatures In | 40c~120c |

| Category | Description | |

|---|---|---|

| A. Load 2.5T (Point Load/Wheel load 0.8T) | Areas where can be used by footways, pedestrians areas, side walking ways, or pedal cyclists. |  |

| B. Load 5T (Point Load/Wheel load 2.5T) | Suitable for use in areas with light Motor vehicle traffic underground parking decks in residential areas. |  |

| C. Load 10.0 T (Point Load/Wheel load 3.0 T) | Areas where can be used by footways, car parks, driveways etc. |  |

| D. Load 20.0 T (Point Load/Wheel load 5.0 T) | Roads for relatively slow moving traffic, i.e minor residential, cul-de-sacs and frequent traffic area. |  |

| E. Load 40.0 T (Point Load/Wheel load 11.5 T) | Areas such as power stations, carriageways, hard shoulders, parking areas for all vehicle types. For high density traffic conditions we recommend the use of vibration resistant locking system. |  |

| F. Load 60.0 T (Point Load/Wheel load 20.0 T) | Areas submitted to high wheel loads such as ports and dikes or dock laterals. |  |

| G. Load 90.0 T (Point Load/Wheel load 40.0 T) | Areas subject to particularly high wheel loads such as runways |  |

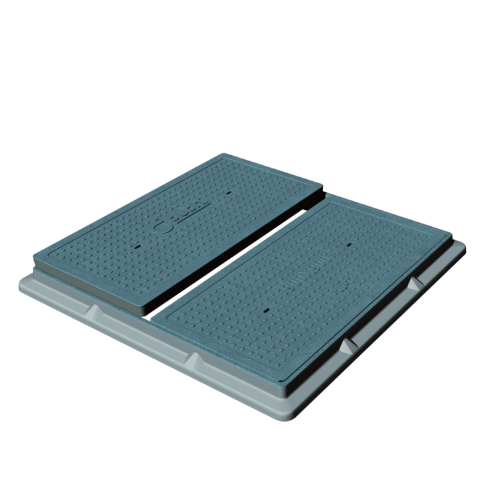

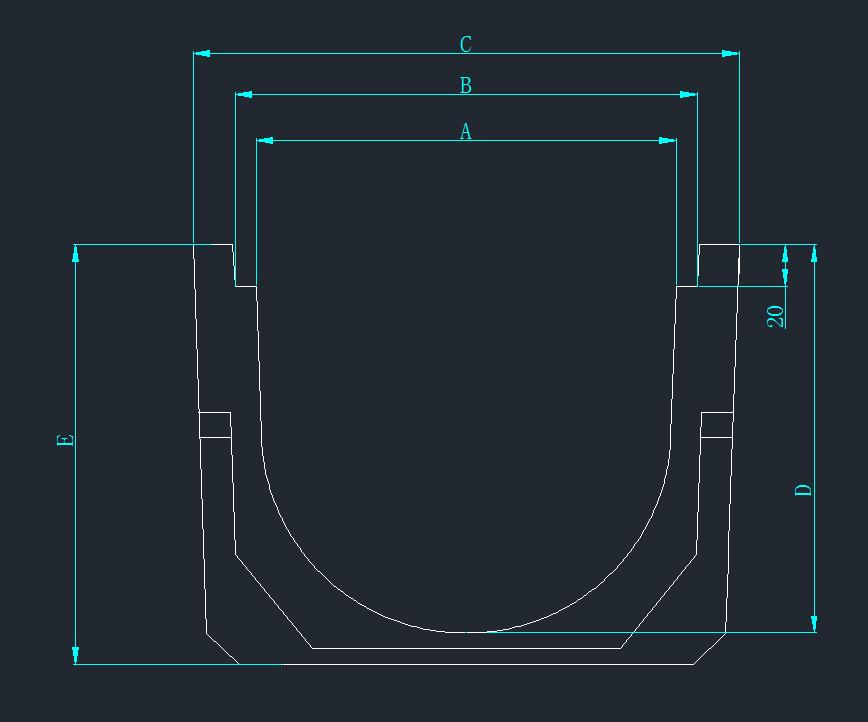

Here are some technical specifications for GFRP drainage channels:

| Description | GFRP Drain Channel |

|---|---|

| Material | GFRP (Glass Fiber Reinforced Polymer) |

| Length | Variable, as per the requirement |

| Width | Between 100mm to 400mm |

| Depth | Between 100mm to 350mm |

| Load Bearing Capacity | Can withstand heavy loads, depending on the thickness and width of the channel |

| Resistance to Corrosion | Highly resistant to corrosion and erosion, ensuring durability and longevity |

| Chemical Resistance | Resistant to a broad range of chemicals, including acids and alkalis |

| UV Resistant | Resistant to UV radiation, ensuring long-lasting color and structural integrity of the channel |

| Fire Retardant | Can be designed to be fire retardant, ensuring safety in high-risk applications |

| Easy to Install: | Lightweight and easy to install with minimal labor and equipment required. |

Overall, GFRP drainage channels offer several advantages over traditional drainage channels, including corrosion resistance, versatility, and durability. They are ideal for use in harsh environments and for applications where traditional materials may fail.

Features