Gypsum Acoustic Plaster

Gypsum Acoustic Plaster

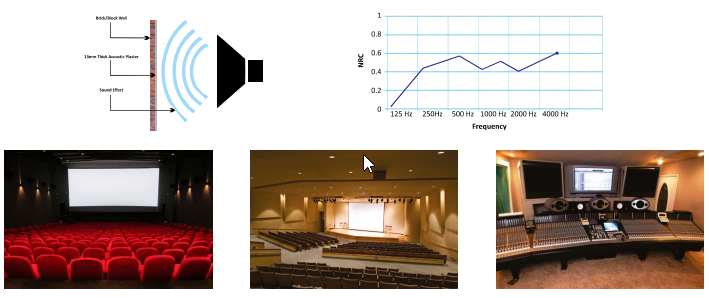

Dudhi Gypsum Acoustic Plaster is an innovative product Introduced by company after DUDHI getting great success of ready mix Gypsum based plaster ie: Brick Solution. This plaster , ewan Ortote rcs is specially formulated and designed as suitable to internal plastering which provides — visually appealing aesthetics, good adhesion on to the walls and ceilings, durable, most economical apart from greater sound absorption (NRC) property. Dudhi Gypsum Acoustic plaster consists with special imported ingredients as Aggregates, additives and Calcium Sulphate . It is ideal for application in Reception areas, Auditoriums, Meeting Rooms, Cinema/Multiplexes, Banquets, Banks, Class Rooms, Sound Recording studios and Educational Institutes where NRC value is more importance.

Technical Specification

| Description | Dudhi Gypsum Acoustic Plaster |

|---|---|

| Setting Time (Minutes) | 22-28 |

| Density kg/m³ | 600-650 |

| Tensile Strength Kg/cm² | 18-22 |

| Compressive Strength N/mm² | 2-3 |

| Coverage 13 mm (kg/m²) | 10.5 |

| Ingredients | Gypsum+ Imported Aggregate + Additive |

| Noise Reduction Coefficient (NRC) | 0.60 |

| Shelf Life | 6 Months from the date of manufacturing |

| Manufacturing | In House |

Consumption of Material

- Consumption Per mm/ Per Sq. Ft.- 0.100 kg

- Coverage 13mm Thickness 30sq-ft/40 kg bag, 19 sq-ft/25 kg bag

Features & Benefits

- Eliminates two-step process of Sand Cement Plaster and POP punning

- Doesn’t require water curing

- No shrinkage cracks

- Non-combustible (when tested in accordance with BS: 476: part 4:1970), therefore a good form of

thermal protection to the building structure. - Use of light weight aggregates in the plaster mix help to improve Low thermal conductivity (0.25

W/m-K) as compared to Sand Cement Plaster (0.72 W/m-K) ** keeps room cooler in summer and

warmer in winter; saving in energy cost - The water absorption as per DIN EN 520 is less < 10%

- Excellent Capillary

- Water absorption coefficient test method —- BS EN 1015-18.

Available Sizes

Identification & Packing

Dudhi Gypsum (Brick Solution) (Moisture Resistant) is packed in PP bags. The outer layer of the bag is printed with the product image, batch number, date of manufacturing, correspondence address and application instructions.

Backed by Superior Service

- Technical service team offers regular site training to use tools and technology to improve

productivity. - Intermediate site inspections and feedback.

- Recommend trained application Team.

- Largely distributed manufacturing capacity.

Testing Standards

- Confirms to IS 2547 (Part |) — 1976 for physical & chemical characteristics

- Confirms to IS 2547 (Part Il) — 1976 for physical characteristics

- HSN Code : 252020, GST : 5%

Certification:

- Conforms and Certified to IS 2547: Part 1 and 2 of “The Bureau of Indian Standard” as per

licence number CML-8400019909 - Meets standards of Green Pro certification and qualifies as green product.

Storage & Handling

Dudhi Gypsum (Brick Solution) (Moisture Resistant) is supplied in 4OKg bags. The dimensions of the bag ensure that a well-filled appearance is presented when filled and the bags can be stacked on a pallet in a stable and well-stacked array. Bags should be stored dry, as absorption of water shortens the setting time, causes set lumps to (*) form in the bags and may reduce the strength of the set plasterwork. No hooks or any sharp tools should be used to carry bags from one location to another.

Application Areas

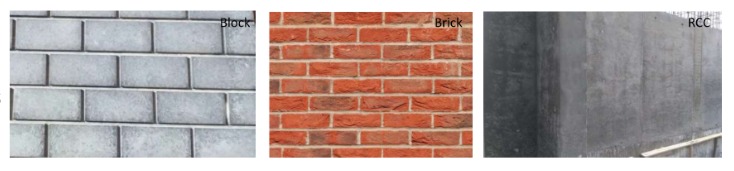

Dudhi Gypsum (Brick Solution) one coat plaster can be applied on most internal surfaces like Bricks, Blocks & RCC (Concrete) surfaces.

Background Preparation

Surfaces should be completely clean, reasonably dry, protected from the direct exposure from weather and suitable for the chosen specification. In addition, before plastering concrete backgrounds, ensure that any mould oil or Concrete Curing Agent (other agents) present are removed from the surface. No-fines concrete does not require wetting prior to plastering. Plaster should not be applied onto a ‘green’ background or when any free water is visible. Clean water should be applied 5-10 minutes before plaster application to control the suction. In-situ or pre-cast concrete which are exceptionally smooth or having low suction will require pre-treatment with Dudhi Plaster Bond bonding agent.

Mixing

Dudhi Gypsum (Brick Solution) (Moisture Resistant) is pre-mixed with aggregate and only clean water needs to be added to prepare it for use. Mixing should be carried out in a clean tray or bucket. Excessive mechanical mixing should be avoided. Tools and water used in mixing must be clean. Contamination from previous mixes can shorten the setting time and in turn reduce the strength of the plaster when set. Water to plaster ratio (1 part of water: 1.5 part of plaster by weight) should be maintained to have good cohesive workable mix. Prepare plaster mix as much as required depending upon the immediate scope of work. Once the mix has begun to set, additional water is not to be added, as performance properties of plaster will get altered, thus affecting workability, cohesiveness, adhesion properties and strength.

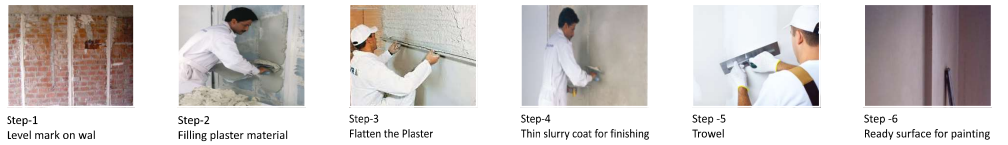

Application

Dudhi Gypsum (Brick Solution) (Moisture Resistant) should be applied with firm pressure, built out to the required thickness, and ruled to an even surface and left as an undercoat to form a key for finish coat. A thin plaster mix is made and applied as a finish coat to provide smooth surface. It can be applied to an average thickness range of 6-15 mm on walls in one coat and up to 10 mm on ceilings. For thickness above this range, material needs to be applied in two coats. The thickness should not increase to more than 30 mm (average thickness) on walls and 20 mm (average thickness) on ceiling. After complete drying for usually 72 hrs (depends upon thickness and weather conditions) the plain smooth leveled surface is ready for painting.

Precautions

- Dissimilar expansion and contraction of RCC and brick / stone masonry could cause stresses and at times separation. To reduce the separation cracks, use of 145 GSM glass fiber mesh (at the junction) is recommended.

- Itis not suitable for use in long continuously damp or severely humid conditions

- If Gypsum Plaster is to be applied on RCC surfaces with the thickness of the application being more than 15 mm then It is to be applied only when moisture is very low and the temperature is more than 10 degrees Celcius because RCC construction has almost negligible porosity as compared to NON-RCC SURFACES. Hence it cannot absorb water.

External Plaster Work Care

In case Dudhi Gypsum (Brick Solution) is applied on internal walls but the exterior cement plaster work of the same wall is pending then Cement Plaster work must be completed prior to painting of the internal walls. Any seepage of moisture during curing from outside will from escape surface of the Gypsum plaster. Please note that the escaping water from Dudhi Gypsum (Brick Solution) may leave some green spots on the surface which can be easily removed with the help of sand paper and then Paint work of the internal walls should be done.

It is not suitable for use in long continuously damp surfaces. For application make the substrate dry and then application to be made.

The information herein should not be read in isolation as it is meant only as guidance for the user, who should always ensure that they are fully conversant with the products and systems being used and their subsequent installation prior to the commencement of work.

Advantages

- Good Acoustic Plaster properties as Noise Reduction Co-efficient (NRC) value – 0.60.

- No Post Curing is required.

- Free from shrinkage cracks.

- Manufacturing with advance technology & special formulation.

- Less wastage and higher coverage makes it economical.

Features