GFRP Fence

Dudhi DynaFence STA GFRP Fence

Application Area:

Introducing Dudhi DynaFence by Dudhi Industries: A New Standard in Security and Durability Dudhi DynaFence, meticulously crafted by Dudhi Industries, signifies a revolutionary leap in fencing technology. Combining the strength of Glass Fiber-Reinforced Plastic (GFRP) with Dudhi’s expertise, DynaFence sets a new standard in security and durability.

- Commercial Buildings ,Industrial Facilities

- Telecommunications ,Healthcare Facilities

- Data Centers ,Power Plants

- Oil and Gas Industry

- Food and Beverage Industry ,Chemical Industry

- Water Treatment Plants ,Pharmaceutical Industry

- Renewable Energy Installations

- Public Spaces ,Pool Enclosures

- Electric Transformer Fencing

- Power House Fencing

- Infrastructure Projects

Application Area

DynaGuard STA :Handrails and Guardrails

Residential Fencing

Safety Fencing

Barricade Fencing

Marine & Coastal Environments

Private Property Gate

Technical Details of Dudhi DynaFence

Material Composition: Dudhi DynaFence is crafted from a composite matrix of plastic resin reinforced with advanced fibers, ensuring superior strength and longevity.

Installation: Lightweight and easy to handle, DynaFence facilitates swift installation, reducing labor costs and time.

Height and Thickness: Available in various heights and thicknesses, Dudhi DynaFence offers customization options,meeting specific security needs and design preferences.

Features of Dudhi Dyna Fence

Exceptional Strength:

Dudhi DynaFence boasts unparalleled tensile strength, providing Robust Protection against Impacts and external pressures.

Corrosion Resistance:

Designed to Resist Corrosion, DynaFence Ensures Longevity Even in Harsh Weather and Corrosive Environments, Outperforming Traditional Metal Fences.

Weather Resistance:

UV-resistant and weatherproof, DynaFence maintains its integrity under prolonged Sunlight Exposure, Making it ideal for outdoor applications.

Low Maintenance:

Dudhi DynaFence requires Minimal upkeep, Eliminating concerns about rotting, warping, or rusting, resulting in long-term cost savings

Customization:

DynaFence can be tailored into various shapes, sizes, and colors, offering creative and personalized designs to match diverse architectural styles.

Eco-Friendly:

Made from recyclable materials, DynaFence contributes to sustainable construction practices, aligning with Dudhi Industries’ commitment to the environment.

Applications of Dudhi DynaFence

Residential Security: DynaFence enhances the security and aesthetics of homes, blending seamlessly with various architectural designs.

- Commercial and Industrial Perimeter Protection: Ideal for safeguarding commercial establishments, industrial sites, and warehouses, DynaFence ensures robust security for valuable assets.

- Agricultural Enclosures: DynaFence is widely used in agriculture, providing secure enclosures for livestock, crop protection, and farm boundaries.

- Public Spaces: From parks to playgrounds, DynaFence ensures safety and delineates boundaries in public spaces.

- Pool Enclosures: Corrosion-resistant, DynaFence is a safe choice for pool areas, enduring exposure to water and chemicals.

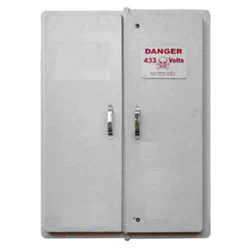

- Electric Transformer Fencing: Specifically designed to secure electric transformers, DynaFence guarantees the safety and integrity of critical infrastructure.

- Power House Fencing: DynaFence offers reliable protection for power houses, ensuring the security of power generation facilities.

- Infrastructure Projects: DynaFence finds applications in bridges, highways, and railways, ensuring durability and resilience in challenging environments.

Technical Details of Dudhi DynaFence:

- Material Composition: Dudhi DynaFence is crafted from a composite matrix of plastic resin reinforced with advanced fibers, ensuring superior strength and longevity.

- Installation: Lightweight and easy to handle, DynaFence facilitates swift installation, reducing labor costs and time.

- Fire Resistance: DynaFence can be treated with fire-resistant coatings, enhancing its fire safety properties, making it suitable for areas with strict fire regulations.

- Height and Thickness: Available in various heights and thicknesses, Dudhi DynaFence offers customization options, meeting specific security needs and design preferences.

In essence, Dudhi DynaFence represents the pinnacle of modern fencing solutions, combining aesthetics, security, and sustainability. Dudhi Industries’ commitment to innovation and quality shines through in DynaFence, making it the preferred choice for a wide range of applications, including critical areas such as electric transformers and power houses.

Materials and Manufacturing Processes :

Pultrusion Process for Manufacturing Dudhi DynaFence STA :

Preparation of High-Quality Raw Materials :

Dudhi Industries begins with selecting top-tier raw materials, including:

- a ) Fiber Reinforcement: Glass fibers or carbon fibers, providing strength and structural integrity.

- b ) Resin Matrix: Premium thermosetting resins like polyester, vinyl ester, or epoxy, offering resistance to environmental challenges.

- c ) Complete Impregnation of Fibers: These chosen fibers undergo meticulous impregnation in a resin bath. Ensuring even coverage, the fibers are primed for their role in fortifying the final product.

- d ) Formation of Ingenious Profile: The impregnated fibers are drawn through a specialized mould, custom-designed for the Dudhi DynaFence STA. This mould accounts for its unique features, such as the fusion of cable tray types and adaptability for accessories.

- e ) Thermal Curing and Solidification: Progressing to the thermal phase, the formed profile enters a heated die, triggering the curing and polymerization process. The resin crosslinks, ensuring strength and endurance.

- f ) Seamless Continuation Through Precision: As the profile solidifies, it advances through the die via a controlled, continuous pulling mechanism. This meticulous approach guarantees uniformity across the product.

- g ) Refined Cutting and Crafting: Post-curing, the profile is cut to desired lengths. Additional precision processes include openings for accessories, ensuring versatility and readiness.

- h ) Exacting Quality Control: Every completed Dudhi DynaFence STA profile is subject to rigorous quality control checks. This step ensures conformance to Dudhi Industries' high standards for strength, dimensions, and performance.

The Dudhi DynaFence STA showcases a blend of innovation and longevity. Through the Pultrusion process, Dudhi Industries crafts lightweight, corrosion-resistant, and reliable cable management solutions, catering to diverse industrial and commercial applications.

Testing and Quality Control :

Testing and quality control play pivotal roles in the production of Dudhi DynaFence STA Fusion Tray, our exceptional FRP (Fiber-Reinforced Polymer) innovation. The meticulous testing and quality assurance procedures encompass the following steps:

- a ) Material Testing: Before integration, the raw FRP material undergoes stringent tests to ensure its integrity. This involves assessing properties like tensile strength, compressive strength, and flexural strength.

- b ) Process Testing: At different stages of manufacturing, our product's quality is scrutinized. This includes evaluating the resin and hardener blend, the curing conditions, and other critical process parameters.

- c ) Physical Testing: Rigorous physical property tests are conducted to ascertain compliance with industry standards. Parameters like strength, stiffness, and dimensional stability are evaluated for adherence to requirements.

- d ) Chemical Testing: Our FRP product's chemical properties undergo thorough examination to meet specified benchmarks. This encompasses assessments for resistance to chemicals, water absorption, and other pertinent attributes.

- e ) Non-Destructive Testing: To ensure impeccable final products, non-destructive testing techniques are employed. Techniques such as ultrasound and X-ray testing detect any defects or imperfections.

- f ) Quality Control: Throughout the manufacturing journey, unwavering quality control checks are implemented. This involves vigilant monitoring of process parameters, meticulous product inspections, and comprehensive quality assurance measures.

In summary, our rigorous testing and quality control protocols are integral to delivering Dudhi DynaFence STA Fusion Tray of the highest caliber. These processes guarantee adherence to standards and ensure that our product stands as a testament to longevity, durability, and excellence across diverse sectors and applications.

Comparison Among Dudhi DynaFence STA & Other Type of Fence

| DESCRIPTION | Dudhi DynaFence STA | MILD STEEL | GALVANISED IRON |

|---|---|---|---|

| Chemical Resistance | Excellent | Low | Low |

| Lift Span | Excellent | Good | Low |

| Acid Fumes Resistance | Excellent | Low | Moderate |

| Electrical Conductivity | Low | High | High |

| Fire Retardant | High | High | High |

| Corrosion Resistance | Excellent | Low | Low |

| Strength to Weight Ratio | Excellent | Low | Good |

| Life Cycle Cost | Low | Moderate | Moderate |

| Rust Proof Features | Excellent | Excellent | Average |

| Ease in Installation | Excellent | Moderate | Moderate |

| Environment Impact | Low | High | High |

| Colour Range | Excellent | NA | NA |