GFRP Rebar

Dudhi DynaBar FRP Rebars

Redefining Construction Excellence Dudhi DynaBar FRP Rebars: Pioneering a revolution in construction, Dudhi Industries proudly presents Dudhi DynaBar FRP Rebars. As a frontrunner in the industry, we usher in a new era of construction excellence, ensuring longevity, strength, and safety in every project.

- Commercial Buildings ,Industrial Facilities

- Telecommunications ,Healthcare Facilities

- Data Centers ,Power Plants

- Oil and Gas Industry

- Food and Beverage Industry ,Chemical Industry

- Water Treatment Plants ,Pharmaceutical Industry

- Renewable Energy Installations

- Public Spaces ,Pool Enclosures

- Electric Transformer Fencing

- Power House Fencing

- Infrastructure Projects

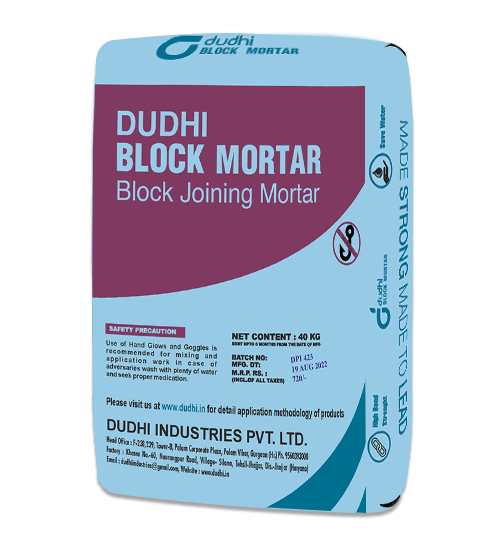

Dudhi DynaBar GFRP Wire Mesh

Weaving a Stronger, Safer Tomorrow for Your Construction Needs!

Building the Future: Strong, Sustainable, Dudhi DynaBar GFRP Rebar

Securing Generations: Dudhi DynaBar GFRP – The Bedrock of Dam Integrity

Boosts child social skills through peer interactions, helping them develop emotional intelligence.

Helps develop positive habits like self-discipline, planning, prioritization, and time management in children.

Application Area

GFRP Rebar for Tunnel Wall & Structures:

Tunnel Linings,Tunnel Floors Tunnel Walls, Tunnel Portals Tunnel Entrance and Exit Ramps, Emergency Exit Passages, Train Tunnel Track Beds

Coastal Construction: Seawalls, Piers and Docks Breakwaters , Harbors Coastal Bridges, Tidal Energy Installations Offshore Wind Farms

Road, Bridge construction

: Used in road construction to reinforce concrete pavements, bridges, and tunnels, enhancing structural integrity and longevity.

Railway Stations

: Station Platforms Station Canopies Station Foundations Station Access Ramps Station Walkways

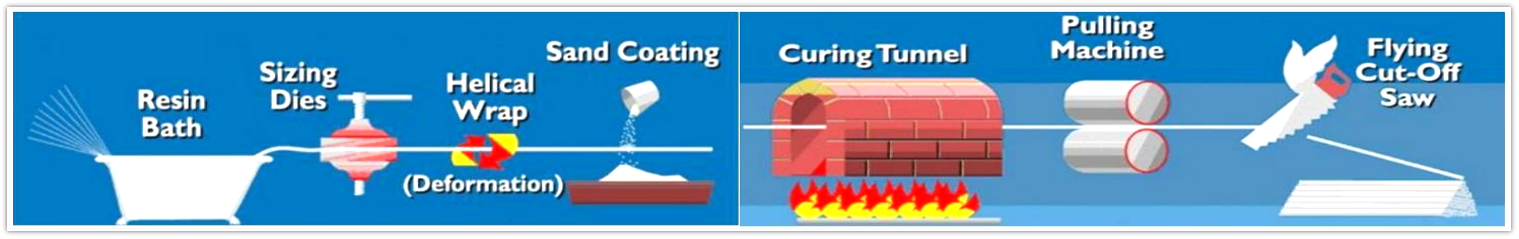

GFRP dynabar production process

Redefining Construction Excellence Dudhi DynaBar FRP Rebars: Pioneering a revolution in construction, Dudhi Industries proudly presents Dudhi DynaBar FRP Rebars. As a frontrunner in the industry, we usher in a new era of construction excellence, ensuring longevity, strength, and safety in every project.

Glass fiber reinforced polymer rebar(GFRP)is made from high technical performance resin (UP/VE/EP/PU)and glass fiber by pultrusion process.

Dudhi DynaBar Key Features

Unrivaled Strength & Durability: Dudhi DynaBar offers exceptional tensile strength, surpassing traditional steel rebars. Lightweight yet incredibly robust, they maintain structural integrity even in the harshest environments.

Corrosion Resistance: Inherently resistant to corrosion, ideal for coastal projects and high humidity regions, ensuring longevity and reducing maintenance costs.

Enhanced Stability: Superior bonding with concrete ensures cohesive support, enhancing stability in buildings, bridges, tunnels, and more.

Innovation & Flexibility: Dudhi DynaBar enables creative freedom, allowing architects and engineers to explore innovative designs previously deemed impossible.

Commitment to Sustainability: Eco-friendly and reducing the carbon footprint, Dudhi DynaBar contributes to a greener future, aligning with our dedication to environmental sustainability.

Dudhi DynaBar GFRP Rebar for Road & Bridge

Dudhi DynaBar FRP in Highway Infrastructure:

Dudhi DynaBar FRP, an advanced composite material, revolutionizes highway infrastructure construction and repair. Lightweight, easily installable, and possessing a remarkable strength-to-weight ratio, Dudhi DynaBar FRP offers unparalleled durability. Tailor-made to specific requirements such as size, strength, stiffness, and overall structure, it aligns perfectly with diverse project needs.

In response to the rising demand for sustainable building materials, Dudhi DynaBar FRP stands out as an ideal choice. It excels in repairing degraded and underperforming concrete infrastructure. By enhancing the strength and performance of existing highway structures, especially in challenging environments that cause deterioration, Dudhi DynaBar FRP delivers exceptional results.

Dudhi DynaBar FRP sets a new standard in highway infrastructure, offering a sustainable, high-performance solution for construction and repair projects.

Suitable Size of Straight Bar

| Diameter | 6 mm | 8 mm | 10 mm | 12 mm | 14 mm | 16 mm | 18 mm | 20 mm |

|---|---|---|---|---|---|---|---|---|

| Weight(g/m) | 50 | 100 | 160 | 230 | 300 | 400 | 490 | 590 |

Dudhi DynaBar GFRP Rebar for Railway Stations

Introduction to FRP Bar Applications in Railway Stations: FRP bars are pivotal components in modern railway station construction, offering innovative solutions for enhanced durability and safety. They find extensive applications in various station structures, ensuring longevity, low maintenance, and structural integrity. Key applications include:

- Station Platforms

- Station Canopies

- Station Foundations

- Station Access Ramps

- Station Walkways

Dudhi DynaBar GFRP Rebar for Tunnel Wall & Structures

Introduction to Dudhi DynaBar Applications in Tunnel Walls and Structures:

Dudhi DynaBar, a leading Glass Fiber Reinforced Polymer (GFRP) rebar solution, has transformed the construction of tunnel walls and related structures. Renowned for its exceptional strength, corrosion resistance, and lightweight properties, Dudhi DynaBar is the ideal choice for ensuring the longevity and stability of tunnels, even in the harshest environments. Its innovative applications are revolutionizing tunnel construction, providing enhanced structural integrity, minimal maintenance, and robust resilience against the challenges within tunnels.

Here’s a closer look at Dudhi DynaBar's key applications:

1. Tunnel Walls: Dudhi DynaBar reinforces tunnel walls, offering unparalleled strength and durability. Its remarkable resistance to corrosion, even in damp and humid tunnel environments, ensures the long-term structural integrity of the walls.

2. Tunnel Structures: Dudhi DynaBar is employed in various structural elements within tunnels, including support structures, arches, and ceilings. Its lightweight yet robust properties simplify construction processes while guaranteeing the required strength, thereby enhancing the overall stability and safety of tunnel structures.

Dudhi DynaBar GFRP Rebar for Coastal Construction

Introduction to Dudhi DynaBar GFRP in Marine Applications:

In the domain of marine engineering, the infiltration of chloride ions poses a substantial threat to the durability of reinforced concrete structures, leading to steel corrosion and structural instability. Dudhi DynaBar, a high-performance Glass Fiber Reinforced Polymer (GFRP) rebar, has emerged as a

potent solution for these challenges. Rigorous laboratory simulations were conducted to evaluate the mechanical properties of Dudhi DynaBar GFRP materials under diverse corrosive conditions, including water, acid, seawater, alkali, and alkali+seawater solutions.

The results showcased exceptional corrosion resistance, particularly in alkali+seawater environments, where Dudhi DynaBar GFRP tendons exhibited no more than a 30% decrease in tensile strength and a modest 12% cange in the elastic modulus.

Moreover, extensive studies explored the resistance of Dudhi DynaBar GFRP bars to alternating dry and wet cycles, revealing outstanding durability. Detailed analysis using Scanning Electron Microscopy (SEM) unveiled that moisture infiltration and OH- played pivotal roles in the deterioration of mechanical properties following corrosion.

Innovative research efforts, supported by proprietary patents, delved into the endurance of Dudhi DynaBar GFRP bars amidst corrosive environments and stress conditions. These studies adhered to the stringent durability requirements, indicating a service life surpassing 60 years. Predictive analyses, based on data and the Arrhenius equation, estimated a lifespan exceeding 50 years for Dudhi DynaBar GFRP bars in marine applications, highlighting their resilience and suitability for marine reclamation projects. This research underscores the immense potential of Dudhi DynaBar GFRP in ensuring the structural integrity and prolonged life of vital coastal constructions.

Comparative Characteristics

| CHARACTERISTICS | Steel | Dudhi DynaBar GFRP |

|---|---|---|

| Material Composition | Carbon Steel | ECR Fiberglass, Epoxy / Vinyl Ester Resin |

| Fiber Content (%) | No Fibres | 75-80% |

| Modulus of elasticity Gpa | 200 | 45-60 |

| Elongation % | 25 | 2 - 2.2 |

| Corrosion resistance to Aggressive media | Subject to Corrosion | 100% Corrosion Proof |

| Heat Conductivity | Heat - Conductive | Non - Heat Conductive |

| Electro Conductivity | Conducts Electricity | Non Conducting |

| Operating Temp. C | -40 to +350 | -40 to +120 |

| Maximum Operating Temp. C | +350 | +100 |

| Ultimate Shear Strength. Mpa | Not rated | 150 |

| Ultimate Compression Strength. Mpa | 350 | 300 |

| Strength of adhesion to concrete. Mpa | Not rated | 12 |

| Density, g/Cm3 | 7.85 | 1.9 - 2.1 |

| Seismic resistance | Depends on the correct selection of reinforcement | Depends on the correct selection of reinforcement |

| Produced profiles. mm | 06 - 80 mm | 04 - 40 mm |

| Length | The rods of length 6-12 m | According to Customer request |

| Environmentally Friendly | Highly polluting MFG. process | Is not Toxic the degree of impact on humans belongs to the 4 hazard class (low hazard) |

| Longevity | Comparative Limited Service LIfe | Predicted life is more than 100 years |

Comparison table of reinforcement characteristics

Steel Reinforcement A-III (A400)

Dudhi DynaBar GFRP

| Ø | Cross Section | Weight I.m. | By Ultimate Limit state | Ø | Weight I.m. | Cross Section | By standard Value | ||

|---|---|---|---|---|---|---|---|---|---|

| MM | M2 | Kg | N | kgf | MM | Kg | M2 | N | kgf |

| Ø6 | 0.0000283 | 0.222 | 9905 | 991 | Ø4 | 0.000008 | 0.024 | 10000 | 1 000 |

| Ø8 | 0.0000503 | 0.395 | 17605 | 1761 | Ø6 | 0.0000212 | 0.046 | 21200 | 2 120 |

| Ø10 | 0.0000785 | 0.617 | 27475 | 2748 | Ø7 | 0.0000302 | 0.066 | 30200 | 3 020 |

| Ø12 | 0.0001131 | 0.888 | 39585 | 3959 | Ø8 | 0.0000407 | 0.078 | 40700 | 4 070 |

| Ø14 | 0.0000154 | 1.21 | 53900 | 5390 | Ø10 | 0.0000567 | 0.115 | 56716 | 5 672 |

| Ø16 | 0.0000201 | 1.58 | 70350 | 7035 | Ø12 | 0.0000865 | 0.202 | 86546 | 8 655 |

| Ø18 | 0.000254 | 2 | 88900 | 8890 | Ø14 | 0.0001227 | 0.256 | 122656 | 12 266 |

| Ø20 | 0.000314 | 2.47 | 109900 | 10990 | Ø16 | 0.0001650 | 0.32 | 165046 | 16 505 |

| Ø22 | 0.000038 | 2.98 | 133000 | 13300 | Ø18 | 0.0002137 | 0.544 | 213716 | 21 372 |

| Ø25 | 0.000491 | 3.85 | 171850 | 17185 | Ø20 | 0.0002687 | 0.62 | 268666 | 26 867 |

| Ø28 | 0.000616 | 4.83 | 215600 | 21560 | Ø22 | 0.0003299 | 0.664 | 329896 | 32 990 |

Standard Dimensions of Packaging

| Diameter | standard "Gazelle" | elongated "Gazelle" | 5-ton truck | Length 20 tons |

|---|---|---|---|---|

| 4 mm | 40,000 | 80,000 | 1,00,000 | 2,80,000 |

| 6 mm | 25,000 | 38,000 | 80,000 | 2,20,000 |

| 8 mm | 17,000 | 24,500 | 45,000 | 1,50,000 |

| 10 mm | 11,000 | 16,000 | 35,000 | 1,40,000 |

| 12 mm | 7,500 | 11,500 | 16,000 | 60,000 |

| 14 mm * | 8,500 - 17,500 | 66,000 | ||

| 16 mm | 8,500 - 17,500 | 42,500 | ||

| 18 mm | 8,500 - 17,500 | 35,000 | ||

| 20 mm | 5,800 - 7,800 | 30,000 | ||

| 22 mm | 5,800 - 7,800 | 26,700 | ||

| 24 mm | 5,800 - 7,800 | 22,800 |

* Loading rates for reinforcement with a diameter of up to 12 mm are indicated taking into account the form of release in coils of 50 and 100 meters. Other sizes are available in bars only. For them the calculation of the load was made using the example of 6- meter rods which do not fir into the “Gazelle” and is impractical to transport them on a Euro-truck.

Weights and diameters of the FRP rebar

| Diameter.mm | Weight of1 m.gram |

|---|---|

| 4 | 23-25 |

| 5 | 38-40 |

| 6 | 54-56 |

| 7 | 75-80 |

| 8 | 94-96 |

| 9 | 110-120 |

| 10 | 142-146 |

| 11 | 170-180 |

| 12 | 196-200 |

| 14 | 292-302 |

| 16 | 450-470 |

| 18 | 550-570 |

| 20 | 620-640 |

| 22 | 720-740 |

| 24 | 840-860 |

Dudhi DynaBar GFRP for replacing steel rebar

| Steel Rebar mm | Dudhi DynaBar GFRP |

|---|---|

| 6 | 4 |

| 8 | 6 |

| 10 | 7 |

| 12 | 8 |

| 14 | 10 |

| 16 | 12 |

| 18 | 14 |

| 20 | 16 |

Standard dimensions of packaging for calculation of logistical costs

| Rods diameter | Length.m | Width.m | Height.m | Volume.m3 | Weight.kg |

|---|---|---|---|---|---|

| 4mm. coil 50 m | 1.2/1.1/0.95 | 1.2/1.1/0.95 | 0.05 | 0.072/0.061 / 0.045 | 1.20 |

| 4mm. coil 100 m | 1.2/1.1/0.95 | 1.2/1.1/0.95 | 0.05 | 0.072/0.061 / 0.045 | 2.40 |

| 6mm. coil 50 m | 1.4/1.2/1.1/0.95 | 1.4/1.2/1.1/0.95 | 0.07 | 0.137 /0.101 / 0.085 /0.063 | 2.70 |

| 6mm. coil 100 m | 1.4/1.2/1.1/0.95 | 1.4/1.2/1.1/0.95 | 0.07 | 0.137 /0.101 / 0.085 /0.063 | 5.40 |

| 8mm. coil 50 m | 1.4/1.2/1.1/0.95 | 1.4/1.2/1.1/0.95 | 0.09 | 0.176 /0.130 /0.109 / 0.081 | 4.70 |

| 8mm. coil 100 m | 1.4/1.2/1.1/0.95 | 1.4/1.2/1.1/0.95 | 0.09 | 0.176 /0.130 /0.109 / 0.081 | 9.40 |

| 10mm. coil 50 m | 1.4/1.2/1.1/0.95 | 1.4/1.2/1.1/0.95 | 0.1 | 0.014 /0.012 /0.011/0.0095 | 7.20 |

| 10mm. coil 100 m | 1.4/1.2/1.1/0.95 | 1.4/1.2/1.1/0.95 | 0.1 | 0.014 /0.012 /0.011/0.0095 | 14.40 |

| 12mm. coil 50 m | 1.4/1.2 | 1.4/1.2 | 0.1 | 0.014 /0.012 | 10.00 |

| 12mm. coil 100 m | 1.4/1.2 | 1.4/1.2 | 0.1 | 0.014 /0.012 | 20.00 |

| 14 mm. inrods of 3 m (10 pcs. In a package) | 3 | 0.1 | 0.1 | 0.03 | 9.00 |

| 14 mm inrods of 6 m (10 pcs in a package) | 4 | 0.1 | 0.1 | 0.06 | 18.00 |

Download Brochure

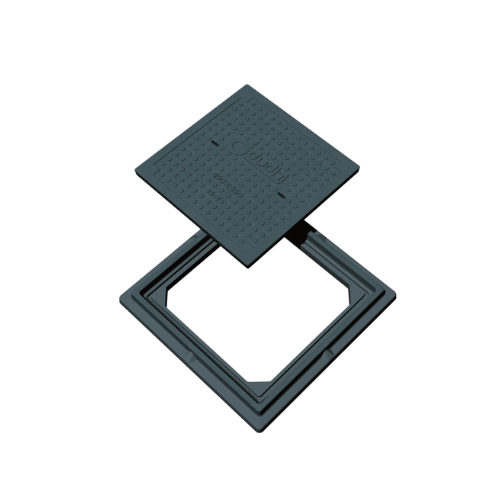

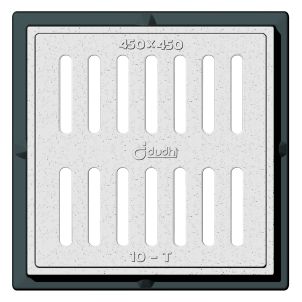

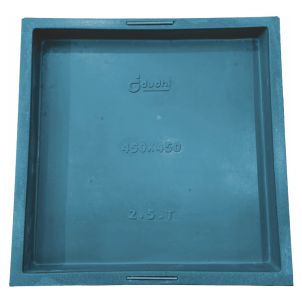

FRP Dudhi Gully Grating:

Fiber Reinforced Polymer (FRP) gully gratings are widely used in various applications due to their lightweight, corrosion-resistant, and durable properties. Gully gratings are designed to cover and protect drainage openings or gully pits while allowing water to flow through. Here are some common application areas for FRP gully gratings