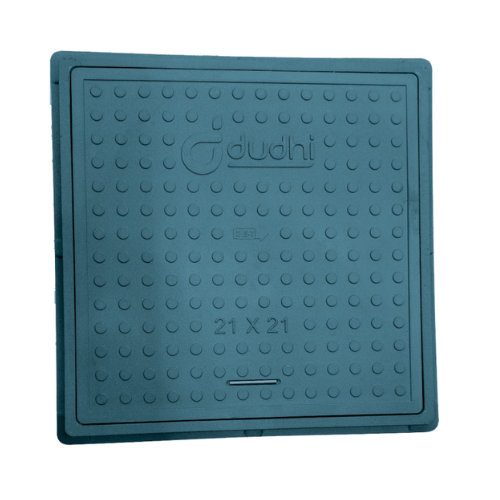

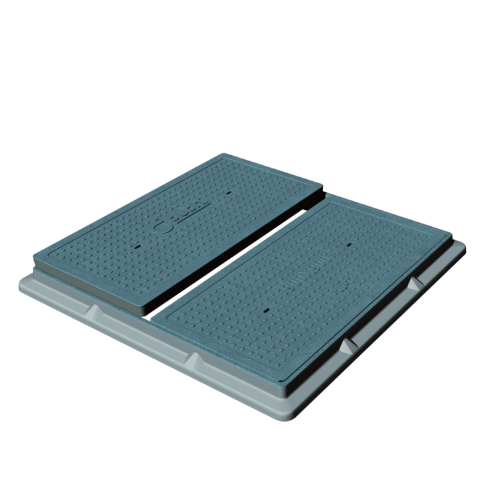

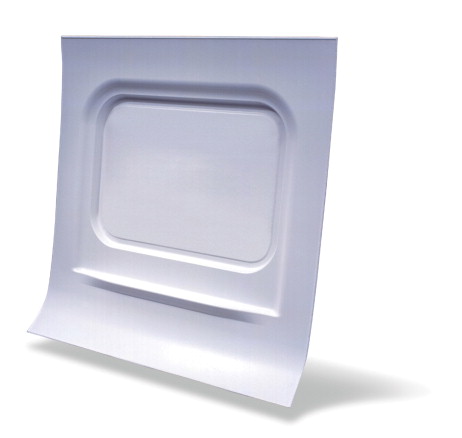

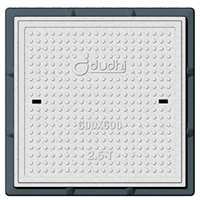

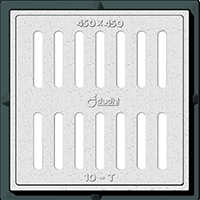

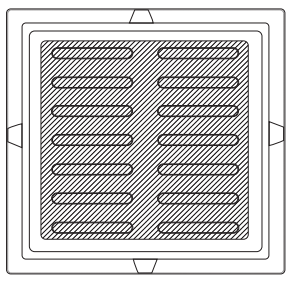

Gully Grating - Square

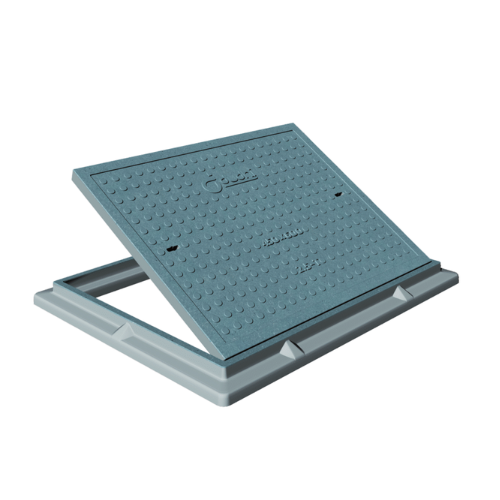

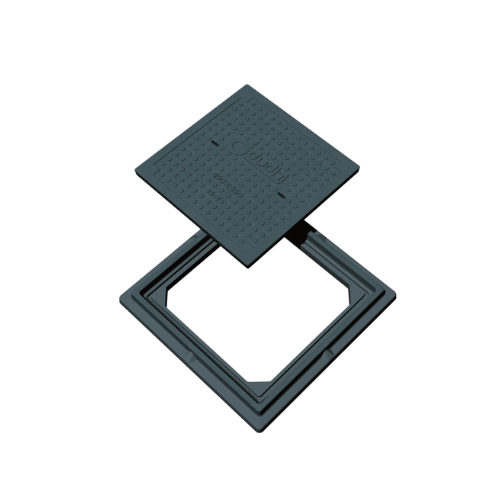

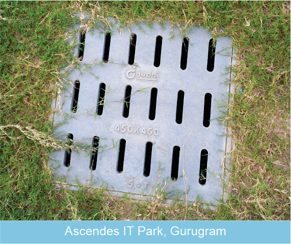

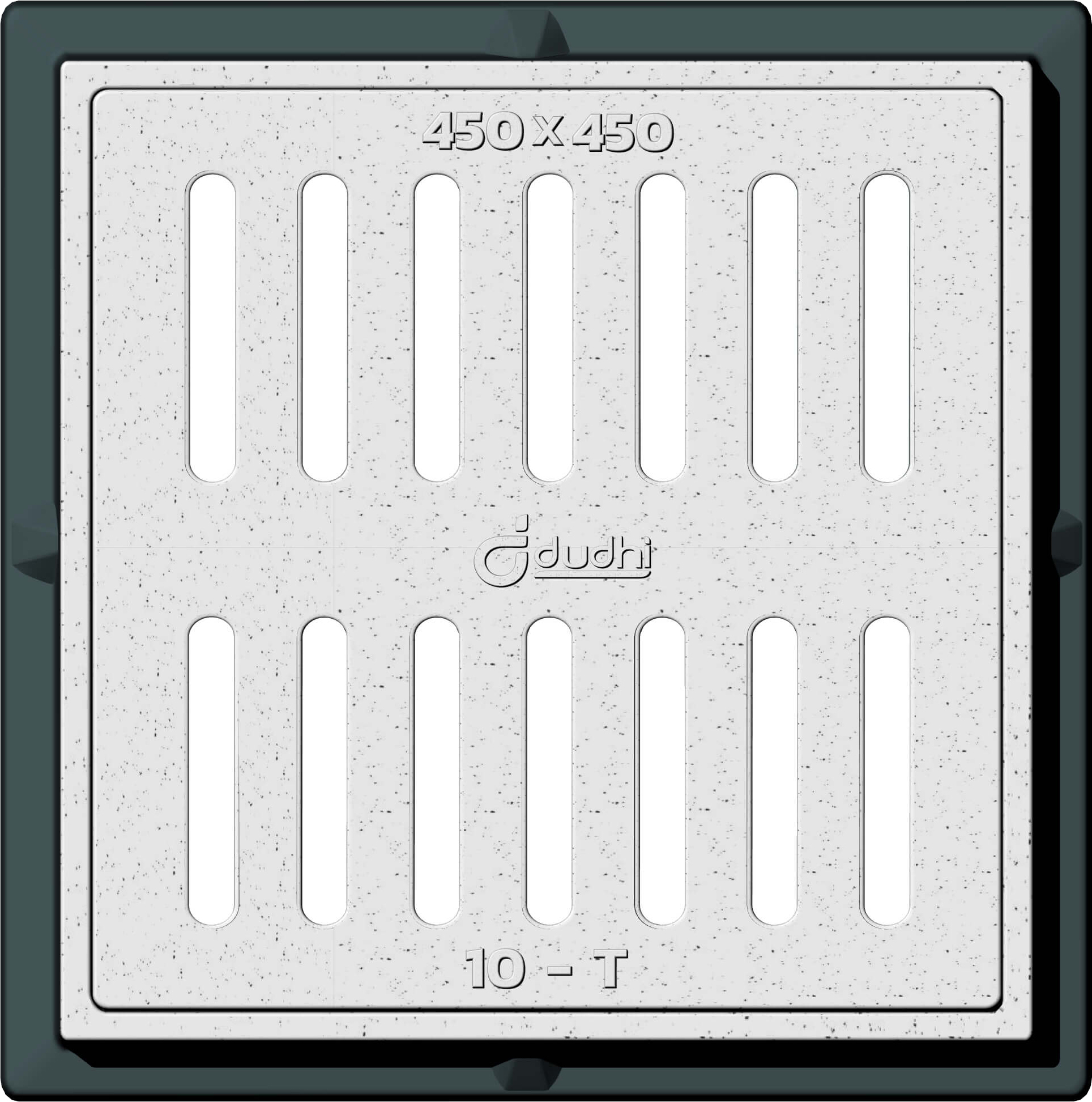

Dudhi Dyna Guard STA: GFRP Gully Grating - Square

- Dudhi GFRP gully grating in square shape are very attractive with it's double slitting rows which provides an aesthetic view when it is fixed on chamber.

- Basically, single chamber in square size fulfill the requirement of draining out the waste/rain water.

- Urban Drainage Systems

- Roads and Highways

- Pedestrian Areas

- Industrial Facilities

- Commercial and Residential Developments

- Marine and Coastal Environments

- Airports, Public Spaces

- Water Treatment Facilities

- Green Infrastructure

- Transportation Infrastructure

- Recreational Facilities

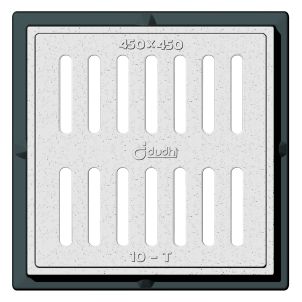

DynaGuard STA : FRP Gully Grating - Square

| Item | Loading Capacity | Clear Opening (mm) (o) | Cover Size (D) | Frame Size (F) | Frame Height (H) | Cover Thickness (h) | Net Weight (KG.) |

|---|---|---|---|---|---|---|---|

| SGS-300 | 2.5/5/10 mt | 300 x 300 | 365 | 450 | 50 | 25 | 13 |

| SGS-300 | 20/40 mt | 300 x 300 | 395 | 500 | 70 | 40 | 24 |

| SGS-450 | 2.5/5/10 mt | 450 x 450 | 495 | 555 | 45 | 30 | 18 |

| SGS-450 | 20/40 mt | 450 x 450 | 520 | 620 | 70 | 45 | 35 |

| SGS-595 | 2.5/5 mt ** | 595 | 30 | 16 | |||

| SGS-600 | 2.5/5 mt | 600 x 600 | 645 | 710 | 50 | 30 | 27 |

| SGS-600 | 10/20/40 mt | 600 x 600 | 665 | 770 | 65 | 40 | 50 |

| SGS-600 | 10/20/40 mt | 600 x 600 | 665 | 770 | 65 | 40 | 50 |

| SGS-750 | 10/20/40 mt | 750 x 750 | 835 | 950 | 80 | 40 | 89 |

| SGS-900 | 10 mt | 900 x 900 | 950 | 1050 | 60 | 30 | 112 |

| SGS-900 | 20/40 mt | 900 x 900 | 970 | 1070 | 100 | 50 | 160 |

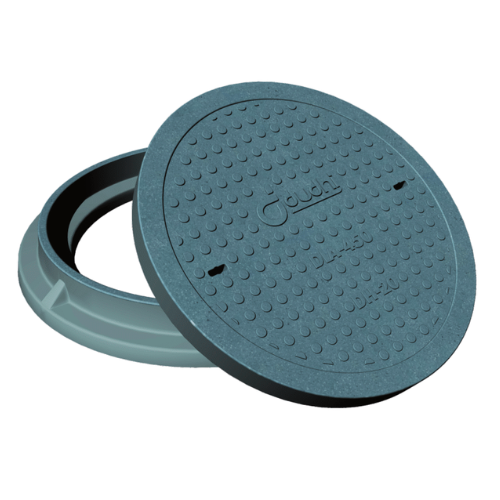

| SGC-560 | 5/10 mt | 560 | 610 | 705 | 55 | 30 | 22 |

| SGC-600 | 5/10 mt | 600 | 680 | 775 | 70 | 35 | 44 |

| SGC-600 | 20/40 mt | 600 | 695 | 815 | 80 | 50 | 53 |

Comparison

| Description | RCC / SFRC | DI / CI | Dudhi DynaGuard FRP | ||||

|---|---|---|---|---|---|---|---|

| Life Span | 5-10 Years | 10-20 Years | Upto 50 years | ||||

| Strength | Low | High | Very High | ||||

| Cost | Low | Moderate | Comparable to CI | ||||

| Weight | Heavy | Heavy | Light | ||||

| Manufacturing Process | Manually Compressed | Manually Casted | Multilayer Composite Unifier | ||||

| Material | Steel, Fibre and Reinforced Concrete | Cast Iron and Duct Iron | Glass Fiber, Resin Aggregate and Additives | ||||

| Water Absoption/ 24 hours | High Water Absorptivity | - | 10-30 mg | ||||

| Carbon Footprint | Very High | Very High | Negligible | ||||

| Scrap Value | Low | High | Nil (Zero Scrap Value) | ||||

| Acid/ Alkaline | Affected | Affected | Not Affected | ||||

| Colour Range | Grey | Black | Wide Range Available | ||||

| Flexibility | Breaks with Load | Bends with Load | High Flexural Strength | ||||

| Custom Design/ Size | Not Always Available | Costly | Available | ||||

| Handling | Difficult | Very Difficult | Easy | ||||

| Compressive Strength | 130-150 Mpa | Wide Range is Difficult | 300-600 Mpa | ||||

| Thermal Expansion | Low | High | Negligible ( Upto 3 to 5 mm Max ) | ||||

| Noise (Vehicle Moving) | Noise is Generated | High Noise Generation | Negligible | ||||

| Strength to Weight Ratio | Very Low | Moderate | Very High | ||||

| Corrosion Resistance | Affected within Short Span | Affected within Short Span | High | ||||

| Abrasion Resistance | None | Yes | Yes |

DynaGuard Products : Unmatched Performance and Durability

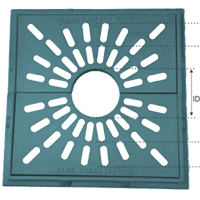

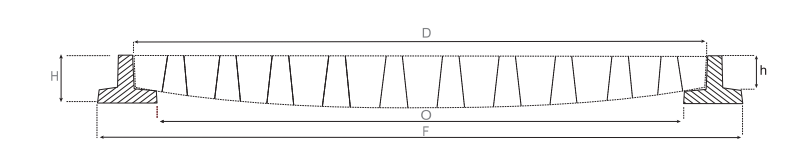

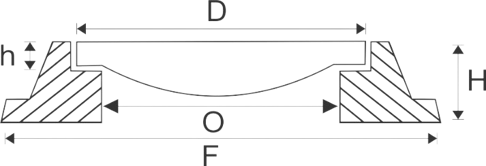

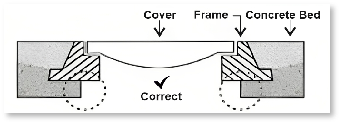

Size Selection

- Clear Opening of the frame should not be smaller than the drain clear opening size.

- Shape of frame should be same as shape of drainage opening.

- If possible, always design drain according to industry standard sizes.

- O – Clear opening

- D – Cover Size

- F – Frame Size

- H – Frame Height

- h – Cover Thickness

Load Bearing Capacity Selection

Load 2.5T (LD) (Point Load/ Wheel Load 0.8T)

Areas where can be used by footways, pedestrians areas, side walking ways, or pedal cyclists.

Load 5.0T (LD) (Point Load/ Wheel Load 2.5T)

Suitable for use in areas with light Motor vehicle traffic underground parking decks in residential areas.

Load 10.0T (MD) (Point Load/ Wheel Load 3.0T)

Areas where can be used by footways, car parks, driveways etc.

Load 20.0T (MD) (Point Load/ Wheel Load 5.0T)

Roads for relatively slow moving traffic, i.e minor residential, r e s i d e n t i a l , cul-de-sacs and frequent traffic area.

Load 40.0T (MD) (Point Load/ Wheel Load 11.5T)

Areas such as power stations, carriageways, hard shoulders, parking areas for all vehicle types. For high density traffic conditions we recommend the use of vibration resistant locking system.

Load 60.0T (MD) (Point Load/ Wheel Load 20T)

Areas submitted to high wheel loads such as ports and dikes or dock laterals.

Load 90.0T (MD) (Point Load/ Wheel Load 30T)

Areas subject to particularly high wheel loads such as runways

DynaGuard Installation and Maintenance

Service-life

Dudhi DynaGuard FRP manhole covers have long durability Upto 50 Years

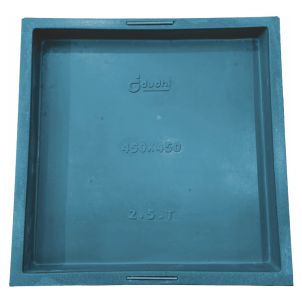

Storage & Handling

Transportation: Lay in flat of manhole cover with a pair of Frame and cover plate during transportation.

Handling: Bigger size of manhole cover is heavier in weight so engage two persons at least to carry in loading or unloading. To avoid damage of corners and edges, keep the cover plate in safe place during fixing of frame.

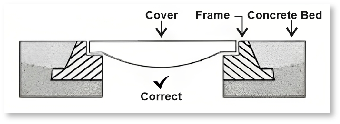

Background Preparation

The foundation of the chamber should be casting the concrete M-30 or even better, the frame around the concrete width should be around 200 mm.

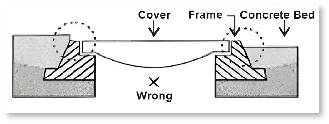

For More Specification Follow Instruction of Dos or Don’ts

Application

Make sure that top level of the frame should match the road.

Prepare concrete bed considering height of the frame

Frame should be allowed to set in concrete for a minimum time of 48 hrs, before its use.

DynaGuard : Precautions

- Do not choose under load capacity it may get damage or harm full during traffic movement.

- During the process if any traffic run on the frame or cover will get damage.

- Do not use hammer or any other tools to open cover from frame. During

- During fixing the frame have to fixed on chamber with proper position not along with cover plate. The cover plate should lay on the frame after completion of flooring work. For more specification Follow instruction of Dos or Don’ts.

Service-life

- Technical Service team offers solutions for application methodology.

- Intermediate site inspections and feedback.

- Recommend appropriate sizes for fixing and finishing.

- Large distributed manufacturing capacity hence easy available in time.

DynaGuard Technical & Physical Parameters:

250-600 Mpa

Longitudinal Strength

300 - 600 mpa

Compressive Strength

25 - 35 Mpa

Stretch Modules

1.3 - 10.0 %

Break Elongation Ratio

700 - 1400 Mpa

Bending Strength

0.35

Poission Ratio

1.11 - 1.15

Relative Density

10 - 30 mg

Water - Absorptive

10 - 30 mg

General - Application Temperature In

250-600 Mpa

Longitudinal Strength

1.3 - 10.0 %

Break Elongation Ratio

250-600 Mpa

Relative Density

300 - 600 Mpa

Compressive Strength

700 - 1400 Mpa

Bending Strength

250-600 Mpa

Water - Absorptive (24h)

25 - 35 Mpa

Stretch Modulus

0.35

Poission - Ratio

250-600 Mpa

General Application Temperatures In