GFRP Drain Channel

Dudhi DynaDrain STA Glass Fibre: Drain Channel

Description: Discover the exceptional benefits of selecting a reputable manufacturer’s Glass Fiber Reinforced Polymer (GFRP) drainage channel, exemplified by Dudhi DynaDrain STA. When opting for a trusted provider like Dudhi Industries Pvt. Ltd. a host of advantages come to the forefront.

These include an Extended lifespan,Effortless maintenance , Eco-consciousness , Unwavering quality , and an Expert post-purchase support.

Thorough research prior to drainage solution acquisition ensures enduring efficacy and robustness for your construction ventures .

Advantages

Effortless Installation: Smooth Surface Minimizes Trenching, Saving Time and Costs.

Unmatched Chemical Resistance : Withstands Heat, Cold, Corrosion, Acids, and Alkalies for Lasting Durability.

End Caps and Accessories: Provide End-caps, Connectors, and Other Accessories that Allow you to customize and configure the drainage system to your specific needs.

Sustainability Focus: Eco-friendly materials ensure environmental harmony.

Concealed Elegance: Seamless linear joints with FRP slot grate cover blend function and aesthetics.

Minimal Upkeep: Low-maintenance design reduces cleaning needs and resource usage.

Application Area

Urban Drainage Systems

Road and Highways

Pedestrian Areas

Residential Areas

Available sizes: Dudhi DynaDrain

Glass Fiber Reinforced Polymer (GFRP) drainage channels are available in a range of sizes, shapes, and configurations to suit various applications and drainage needs. Here are some aspects that are typically available for GFRP drainage channels:

- Width (O): 100 mm to 300mm

- Depth(H): 100 to 350 mm,

- Length: 1000mm

- Loading Capacity 2.5 ton. To 10 Ton.

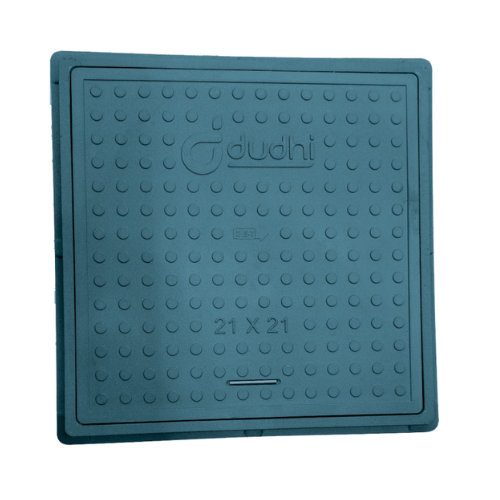

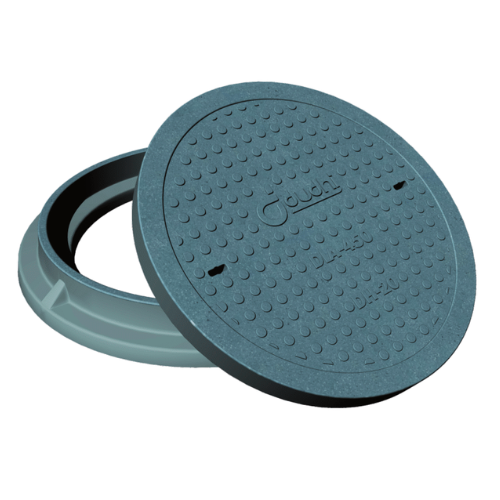

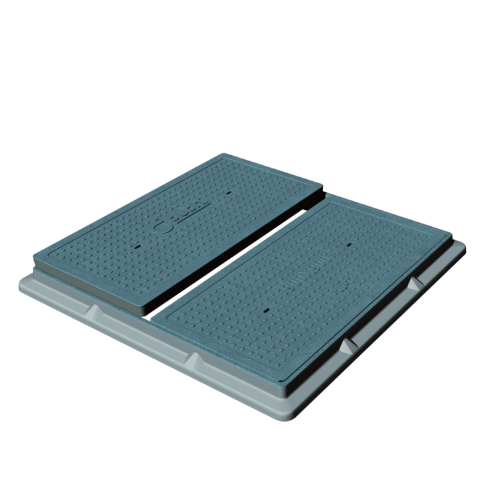

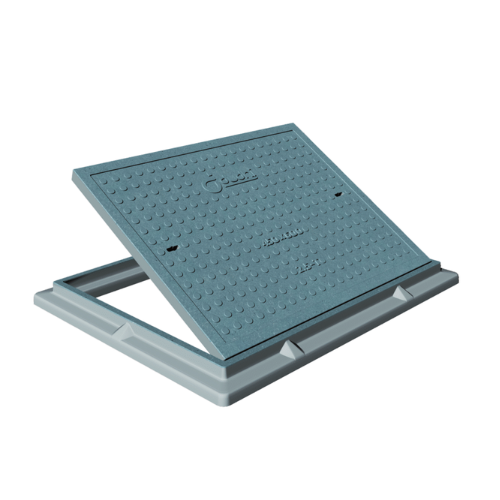

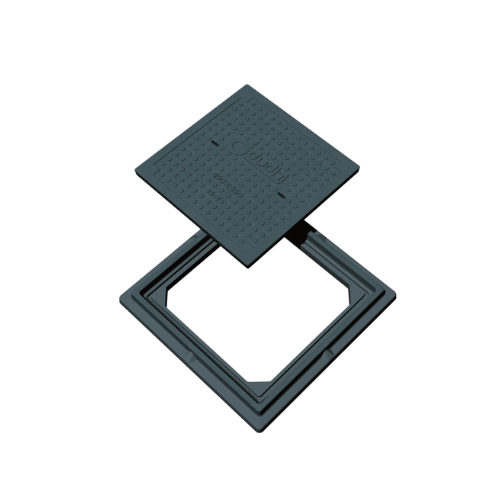

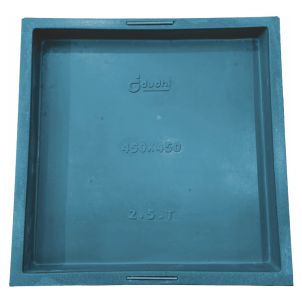

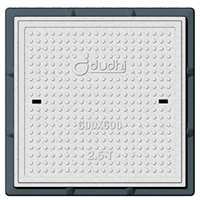

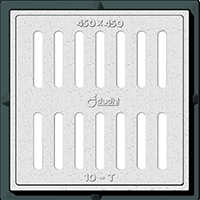

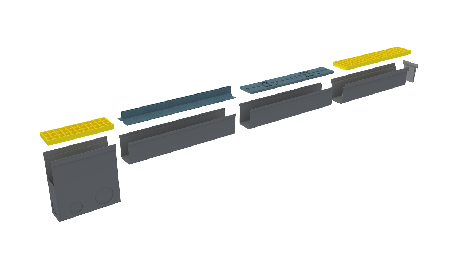

Dudhi DynaDrain STA Covers

Dudhi DynaDrain STA Channel are available in variety of cover choices as per buyer’s and application requirements. The drain channels are customised according to right fitment of Covers selected by the buyer.

The gap-type linear drainage system has good drainage capacity. It is very suitable for installation in places with high requirements for paving landscapes. The system can be used with almost all ground auxiliary materials and has good bearing capacity. The gap-type drainage system is composed of a steel gap-type cover plate, resin concrete drain ditch base, falling water well, inspection-well system accessories, and another modular integrated drainage system.

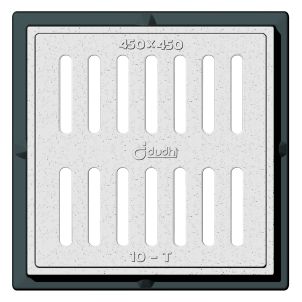

Gully Grating :

Length 500 MM

Width : 120 to 330 MM

Height : 20, 25 & 30 MM

Slide Slot Covers :

Length : 1000mm

Width : 120mm-330mm

Customized Height : 40mm, 60mm, 80mm

Internal Size Of The Gap : 12mm or Customized*

Moulded Grating Covers :

Square Mesh(38 x 38 mm ) RibThickness-(5-7 MM)

Height : 25 MM for 2.5 T Load

Square Mesh(38 x 38 mm )

RibThickness-(5-7 MM)

Height : 30 MM for 5.0 T Load

Square Mesh(38 x 38 mm ) RibThickness-(5-7 MM) Height : 40 MM for 10.0 T Load

Comparison

| Description | RCC | Polymer Concrete | Dudhi DynaDrain STA |

|---|---|---|---|

| Strength | Offers high compressive and tensile strength, but it is brittle and has the low flexural capability. | Polymer Concrete also has high compressive strength, but its tensile and flexural strength is less when compared to RCC. GFRP | Moderate compressive strength but excellent tensile and flexural strength, making it suitable for applications requiring high strength and durability. |

| Weight | RCC is a heavy material, which makes it cumbersome to transport and install. | Polymer Concrete is relatively lighter compared to RCC,with approximately 50% less weight. | DynaDrain STA, however, is the lightest of the three, with its weight being only 25% compared to RCC. |

| Durability | RCC has excellent durability However, it is prone to cracking and spalling due to thermal stresses and freeze-thaw cycles. | Polymer concrete also has excellent durability but is less resistant to chemicals and thermal shocks. | DynaDrain STA is highly durable and corrosion-resistant, making it an ideal choice for harsh environments. |

| Installation | RCC requires heavy machinery and skilled labor for the installation, making it a time-consuming process. | Polymer concrete has a fast setting time but requires specialized equipment for installation. | DynaDrain STA is lightweight and easy to handle, enabling quick and easy installation. |

| Maintenance | RCC requires periodic maintenance due to cracking, spalling, and corrosion of steel reinforcements. | Polymer concrete requires minimal maintenance, but surface corrosion can occur over time. | DynaDrain STA requires the least maintenance, as it is resistant to corrosion and damage from harsh environmental conditions. |

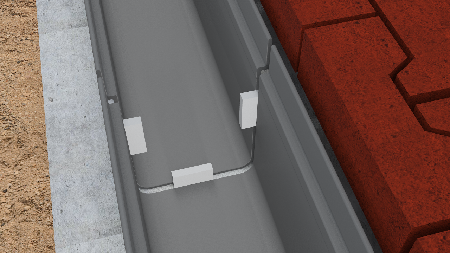

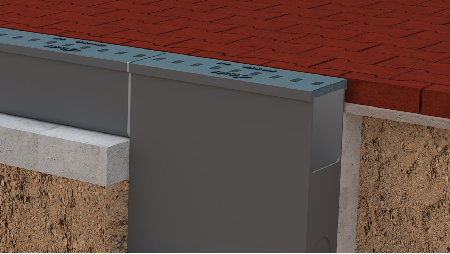

Installation Guidelines for Dudhi DynaDrain STA Drain Channel

Please note frame is not load bearing and therefore has to be completely supported from all sides. For more specification follow instruction of installation.

- Preparation: Assess site conditions and drainage needs. Gather necessary tools and equipment.

- Site Layout: Determine optimal placement and slope. Mark installation positions accurately.

- Trench Excavation: Dig a trench to accommodate the drain channel.Ensure proper width and depth.

- Surface Leveling: Ensure a flush surface around the drain channel.

- Channel Placement: Carefully position the drain channel. Align with marked slope and location.

- Surface Leveling: Ensure a flush surface around the drain channel.

- Grating Fixing: Place and secure the grating or cover. Prevent debris entry while allowing water flow.

- Backfilling: Fill trench with backfill material. Compact material in layers to avoid settling.

- Substrate Preparation: Compact trench bottom evenly. Create a stable foundation if needed.

- Water Flow Test: Test drainage by pouring water and checking flow.

- Secure Connections: Attach sections securely using proper connectors. Seal joints with approved sealants.

- Safety First: Adhere to safety protocols, especially in deep trenches. Wear appropriate personal protective equipment (PPE).