SMC Products

SMC Products

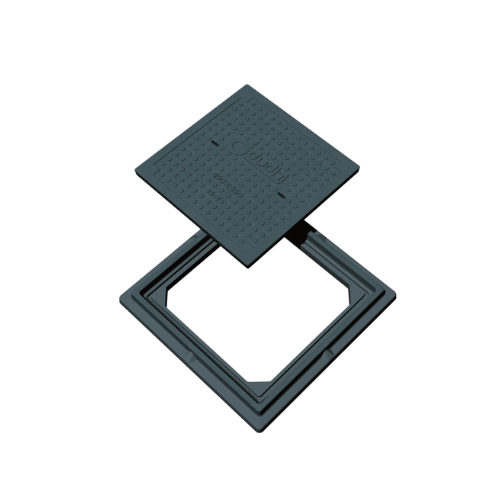

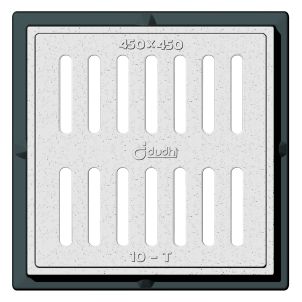

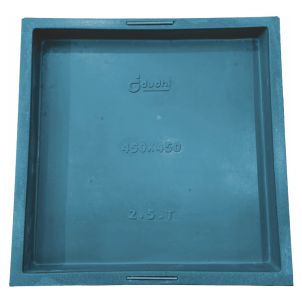

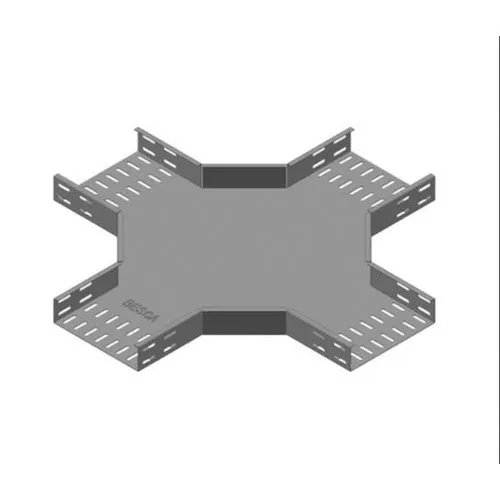

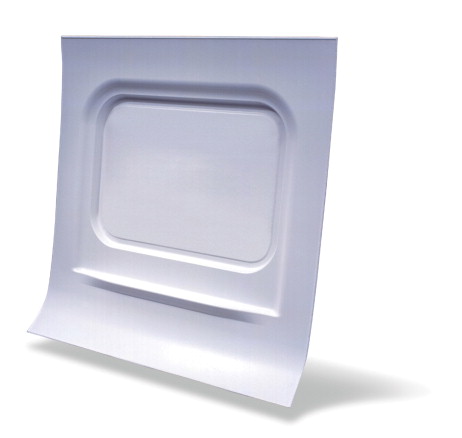

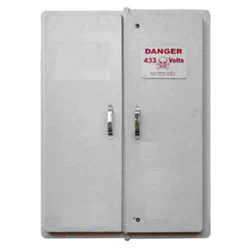

SMC, or Sheet Molding Compound, is a composite material consisting of resins, glass fibers, and additives. To create SMC products, the material is prepared by mixing these components and then compressed into a mold cavity. Heat and pressure are applied to cure the material, activating the resin and forming the final product. Once cured, the product is demolded, trimmed, and finished as necessary. The process allows for the production of complex shapes with tight tolerances and offers advantages such as high production rates and excellent repeatability. SMC products are valued for their lightweight, durable, and corrosion-resistant properties, making them suitable for various applications across industries.

SMC Products

the Advantages of SMC Products

High Strength:

Exceptional strength-to-weight ratio.

Lightweight:

Easy handling and installation.

Corrosion Resistance

Ideal for outdoor use.

Design Flexibility:

Complex shapes with precision.

Dimensional Stability:

Maintains shape over time.

Electrical Insulation:

Non-conductive properties.

Chemical Resistance:

Withstands harsh environments.

Cost-Effective

Efficient production for savings.

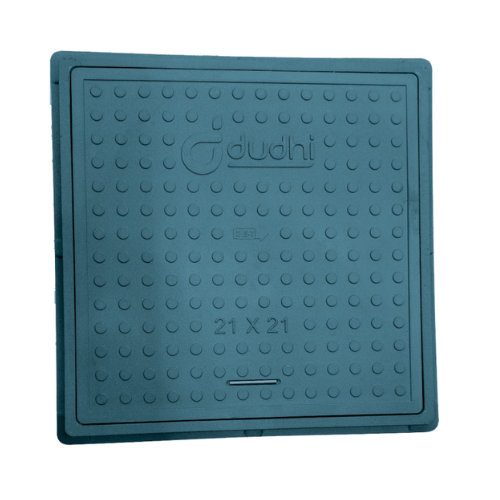

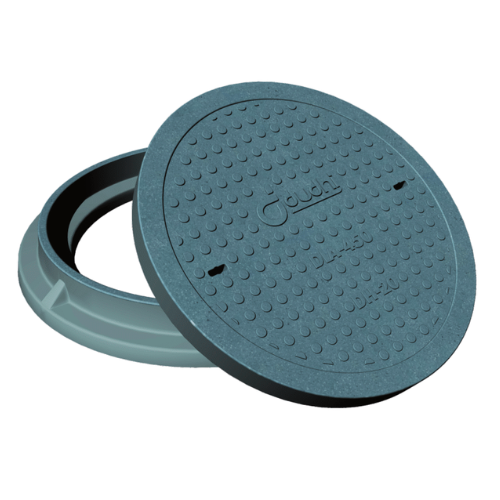

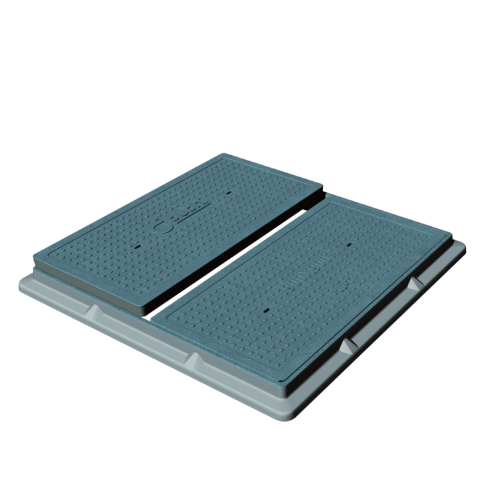

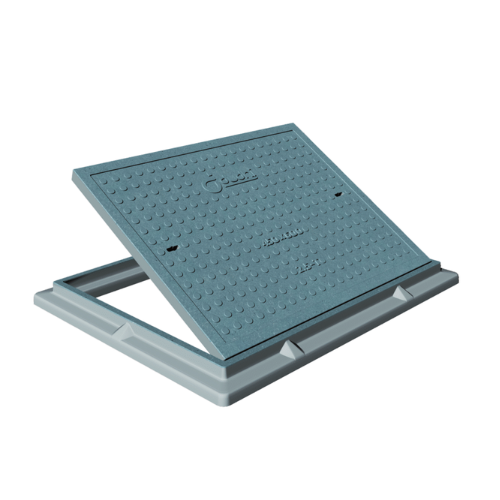

Products We have on SMC Products

Best Quality

The reasons why you should choose our product!

Construction is a general term meaning the art and industrial science of old french construction building solution.

- 1. Quality Assurance: Rigorous standards ensure top-tier durability and performance.

- 2. Innovative Solutions: Cutting-edge technology meets evolving construction needs.

- 3. Versatility: Tailored options for a wide range of construction projects.

- 4. Longevity: Engineered for enduring strength and resilience.

- 5. Customization: Flexibility to adapt to your specific project requirements.

- 6. Sustainability: Eco-conscious materials and practices for a greener future.

- 7. Exceptional Support: Dedicated assistance from selection to installation.

- 8. Proven Reliability: Trusted by industry professionals for consistent excellence.

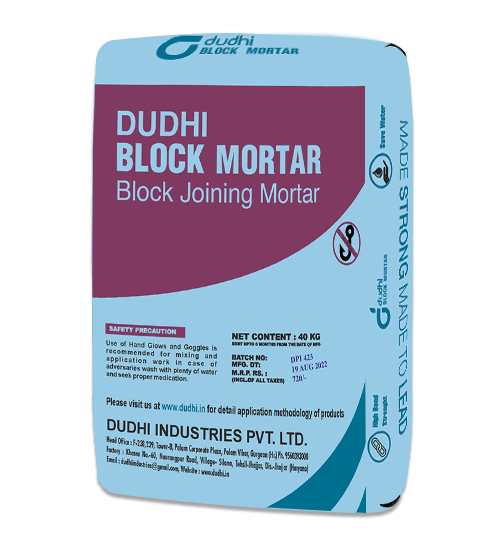

Dudhi 's

Quality Control Process

01

Procurement Control

Of Raw Materials:

All chemicals, components & materials are properly identified and recorded with name, code, lot number, receiving date, and expiration date on the receiving report. All the incoming materials are then tested as per parameters specified in Certificates of Analysis. All records are maintained under procurement team and are filed for next 6 months.

02

IN-PROCESS QUALITY CONTROL :

We keep vigilant control at every stage of manufacturing process, adhering to our in-house measures of quality control

03

FINISHED PRODUCTS QUALITY CONTROL :

We have well established laboratory and all products are tested as per specifications, norms and quality standards set by BUREAU OF INDIAN STANDARDS or EN standards (where Indian standards are not available yet).

Products are dispatched after final approval from Quality Control Department.

Other Product Categories

Some Other Products We’re Offering

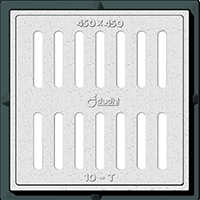

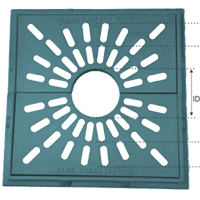

GFRP manhole covers are environmentally friendly because they can be recycled and do not generate dust during installation or use. They are also easy to install and maintain, which reduces labour costs and minimizes the need for frequent replacements

GFRP pultrusion products are structural elements and components made using a continuous manufacturing process called pultrusion. This process involves pulling continuous glass fibers through a resin bath, where they’re impregnated with a polymer resin.

We also offer a range of cement-based products to meet your needs, including Tile adsive, cement plasters, and cement putty. These products are perfect for a range of applications, including building facades, roofs, and more.

Our FRP innovative planters are made from high-quality fiberglass-reinforced plastic, Our FRP innovative planters are perfect for adding a touch of nature to your spaces. They are available in a variety of sizes and designs, and are made from high-quality materials to ensure that they last for years to come.