The construction industry is undergoing a significant transformation with the advent of new materials and technologies. Among these innovations, Dudhi Dynabar GFRP rebars are leading the charge, offering unmatched benefits over traditional steel rebars. In this blog, we will explore how Dudhi Dynabar GFRP rebars are changing the construction landscape with their superior performance, sustainability, and cost-effectiveness.

What are GFRP Rebars?

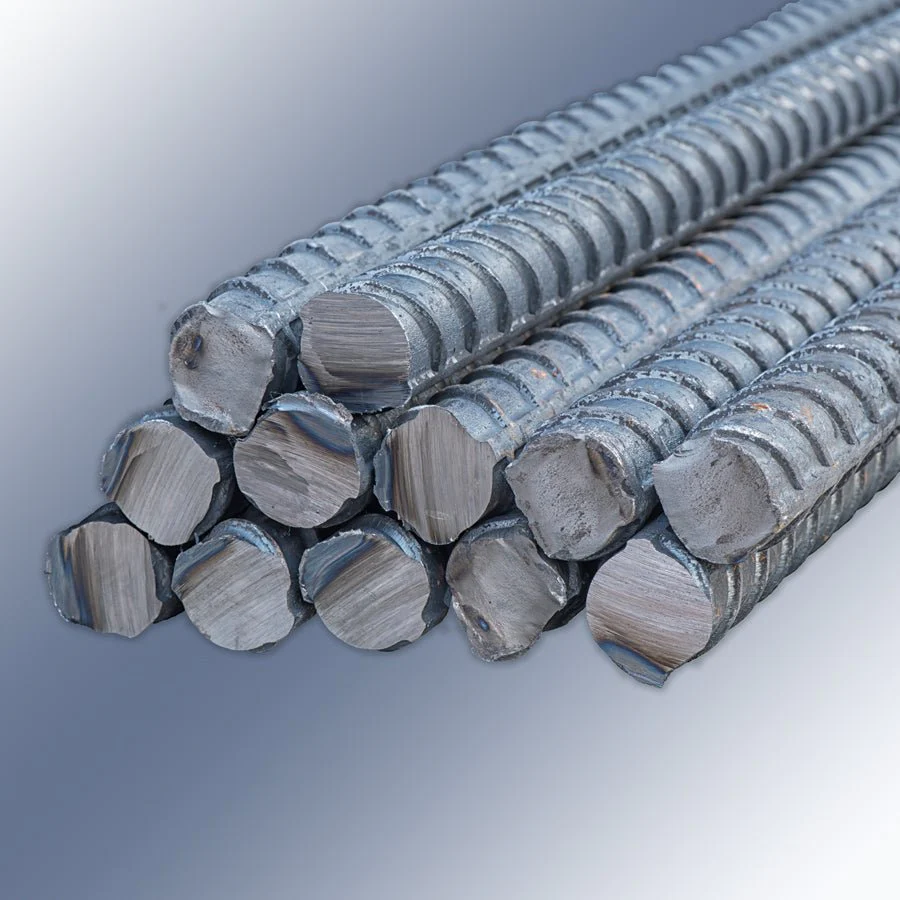

Understanding GFRP Rebars: Glass Fiber Reinforced Polymer (GFRP) rebars are composite materials made from high-strength glass fibers embedded in a polymer matrix. Unlike steel, GFRP rebars do not corrode, making them an ideal choice for various construction applications. These rebars are known for their exceptional strength, lightweight nature, and resistance to environmental factors.

Advantages of Dudhi Dynabar GFRP Rebars

Corrosion Resistance: Traditional steel rebars are susceptible to rust and corrosion, especially in harsh environments. Dudhi Dynabar GFRP rebars offer superior corrosion resistance, ensuring the longevity and durability of structures.

Lightweight Construction: GFRP rebars are significantly lighter than steel rebars, which reduces transportation costs and simplifies handling and installation. This results in faster project completion and lower labor costs.

High Tensile Strength: Despite their lightweight nature, Dudhi Dynabar GFRP rebars provide high tensile strength, enhancing the overall strength and stability of the structures they reinforce.

Sustainability: GFRP rebars contribute to sustainable construction practices by reducing the need for frequent replacements and maintenance. Their long lifespan means fewer resources are consumed over time, aligning with eco-friendly construction trends.

Non-Magnetic and Non-Conductive: GFRP rebars are non-magnetic and non-conductive, making them ideal for specialized applications where magnetic interference or electrical conductivity is a concern, such as MRI rooms and electrical substations.

Applications of Dudhi Dynabar GFRP Rebars

Infrastructure Projects: GFRP rebars are perfect for infrastructure projects like bridges, highways, and tunnels, where durability and longevity are crucial. Their resistance to harsh weather conditions ensures long-term performance.

Marine Structures: In marine environments, where exposure to saltwater can cause rapid corrosion of steel, GFRP rebars are an excellent alternative. They are ideal for piers, docks, and coastal buildings.

Industrial Facilities: Chemical plants, waste treatment facilities, and other industrial settings benefit from the chemical resistance and non-conductive properties of GFRP rebars.

Residential and Commercial Buildings: GFRP rebars enhance the structural integrity and lifespan of residential and commercial buildings, providing a reliable alternative to traditional materials.

Technical Specifications and Standards

Compliance with Industry Standards: Dudhi Dynabar GFRP rebars meet international standards such as ASTM, ACI, and CSA. Their technical specifications include high tensile strength, modulus of elasticity, and shear strength, making them a reliable choice for various construction needs.

Future of Construction with GFRP Rebars

Innovation and Advancements: Dudhi Industries is at the forefront of ongoing research and development in GFRP technology. As the construction industry continues to evolve, GFRP technology will play a crucial role in shaping the future of sustainable and resilient infrastructure.

Sustainable Construction Trends: GFRP rebars align with the broader trend towards sustainable construction practices. Their long lifespan and reduced need for maintenance make them an eco-friendly choice that contributes to the sustainability goals of the construction industry.

Conclusion

Dudhi Dynabar GFRP rebars are revolutionizing the construction industry by offering a durable, sustainable, and cost-effective alternative to traditional steel rebars. As the industry continues to evolve, GFRP technology will play a crucial role in shaping the future of construction.

Call to Action: Learn more about Dudhi Dynabar GFRP rebars by visiting our website, contacting our team for more information, or exploring additional resources on our blog.